Disclaimer: As part of my October trip to Taiwan, I was invited to tour the Evergreen Group HQ hangars and catering facilities.

Evergreen Group, the Taiwanese corporation that encompasses cargo shipping, hotels, flight training, UNI Air, and of course, EVA Air, has quite the set-up in Taoyuan, where Taipei’s primary airport is located.

Indeed, a number of airlines — not just Taiwanese — get their maintenance work, and food service functions done at the Evergreen Group HQ. By the way, Evergreen Group was founded in 1968, although EVA Air only made its first flight on 1 July, 1991.

First, the small group had a brief tour of the hangars, called Evergreen Aviation Technologies Corp (EGAT). Not only was Evergreen Group staff in charge of EVA Air and UNI Air (a small regional Taiwanese carrier) repairs, but also for a number of other airlines and aircraft types. Having only ever seen one other hangar — the Boeing Everett Facility outside of Seattle — as a child, this Taoyuan facility was a sight to behold.

To be candid, a large part of the hangar facilities did not allow photography, so these two will have to suffice.

ln terms of how many aircraft the personnel can undertake MRO (maintenance, repairs, overhaul) at any one time, that amounts to nine wide-bodies, and three narrow-bodies.

In fairness, as much as I was excited to see the hangars, I was really drawn into the catering facilities. I used to e-mail airline caterers such as Do & Co. and Swissport just to inquire about taking tours…always to no avail.

But finally, the EVA Air trip came through….

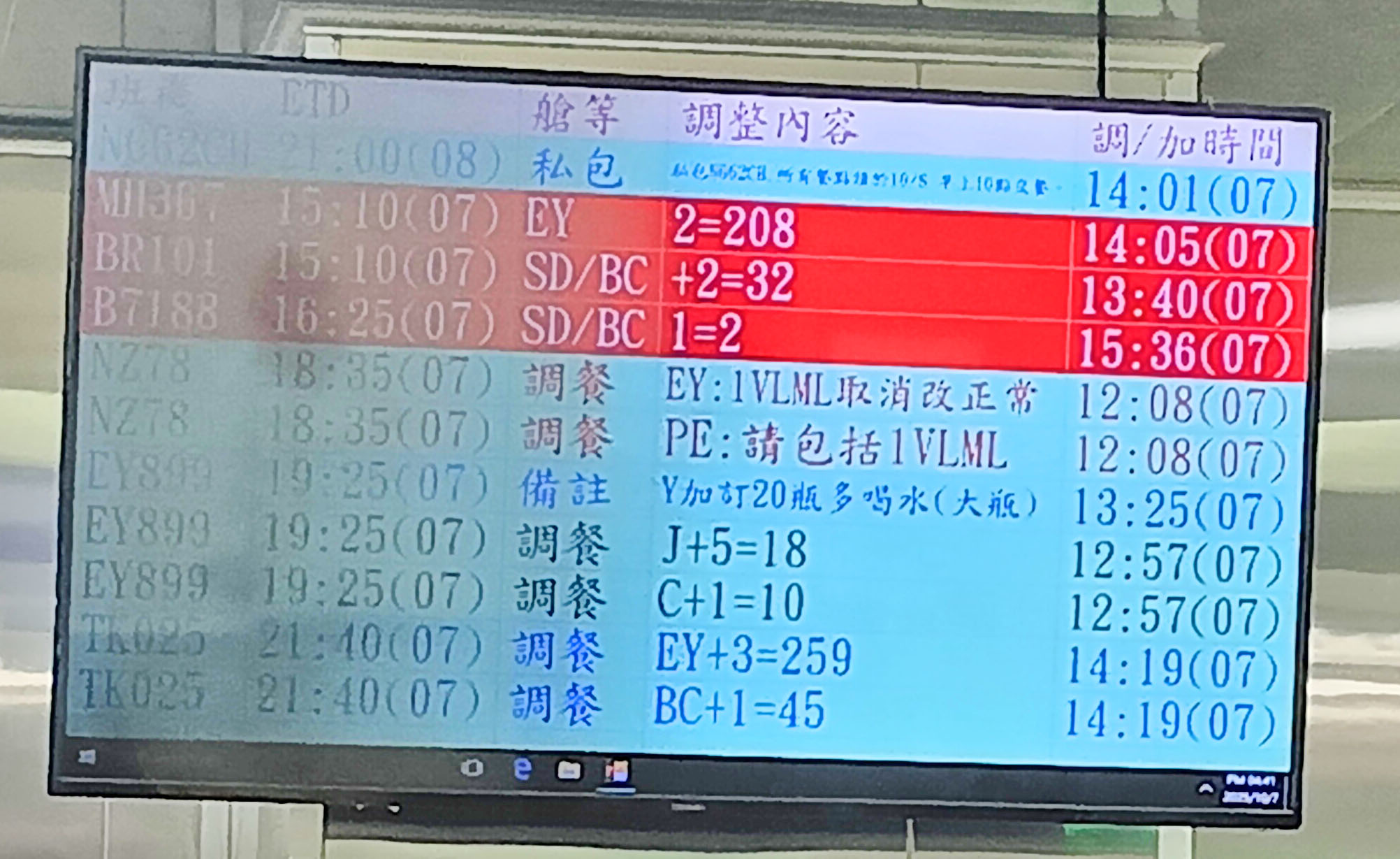

Evergreen Sky Catering Corporation (ESCC) handles a number of flights in Asia-Pacific, in particular carriers looking for Halal caterers. ESCC has found a “niche” in Halal in-flight food service, and continues to grow that sector. Thus, alongside EVA Air and Air New Zealand, you will see Turkish Airlines, Etihad, and Malaysian Airlines, among others.

But before any of that, let’s take a glance at what staff must do on a daily basis, just to enter the building.

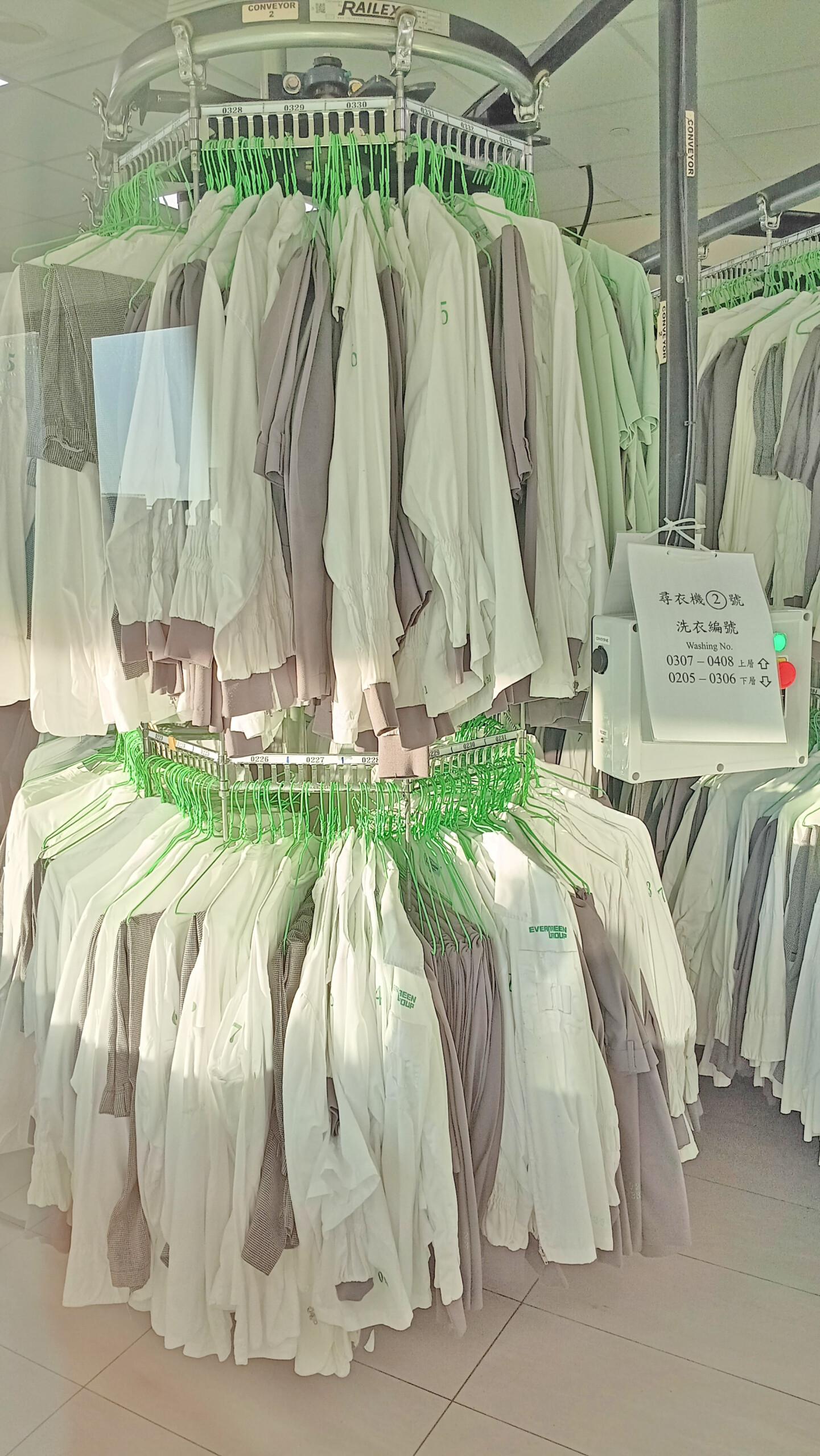

First, each worker has to take a uniform designated with a 1-7 on it; the number corresponds to the day of the week.

Then, there’s this compressed air room that aims to rid staff members of harmful particulate matter.

In the background is a pad to clean footwear.

Finally, we have this sink.

Unless the employee washes hands for a specified minimum amount of time, it will not be possible (well, not reasonably possible) to exit this room.

Bonus: for when things get too busy, there are some capsules to spend the night.

OK, now that we’re dressed the part, let’s take a look at the immaculate catering area.

Heading down the hall–

Signage was a great, task areas were clearly demarcated, and no, samples weren’t handed out. Right?

Just kidding about not getting samples; after all, the press team was right there.

It was a very cool experience to see both the Evergreen Group HQ hangars and catering facilities, with the only problem being that I now want to see more of them.

Leave a Reply